|

You may already read alot of news or media talk about printing rabbit heart , boat or building.

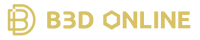

Those media always make 3D printing technology sound like just one push button it done by itself. Well I am Bruce lets back to basic. 3D Printing is a desktop version of Additive manufacuring. Yes, in theory it can build amos everything , But! 3D Printing technology is not one thing. is a category it includes the plenty type of technology. One of the most common desktop 3D Printing is FDM technology. FDM Fused Deposition Modeling/ FFF Fused Filament Fabrication side noted: This two are same thing. If you interested why one technology got two name click here FDM/FFF the additive manufacturing method in which a detail is created layer by layer by melting a plastic wire and applying it through a heated nozzle. check the picture below :

1 Comment

You may hear about industrial 4.0 every where and you may already know 3D printing is part of the "4.0" Incase you never hear about here is what from wikipedia just incase here is Wikipedia info. Components of Industry 4.0 “Industry 4.0” is an abstract and complex term consisting of many components when looking closely into our society and current digital trends. To understand how extensive these components are, here are some contributing digital technologies as examples:[24]

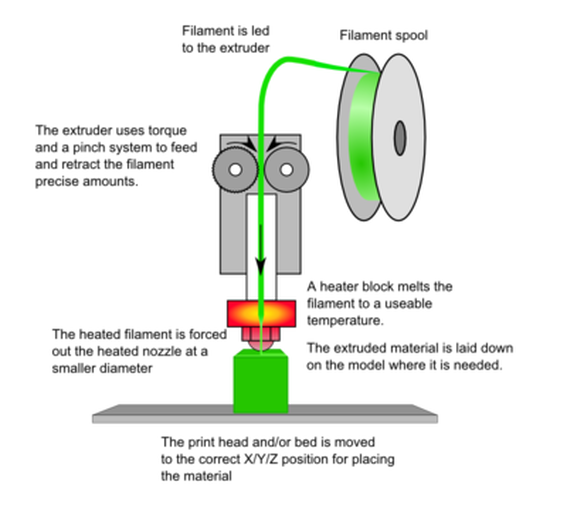

yeah there is alot of topic. Lets just talk about 3D printing If you follow 4.0 news you must see this" 3D PRINTING IS A BIG COMPONENT OF INDUSTRY 4.0 while alot of people still do not understand 3D printing, Media start buzz 4D Printing ... ok not much to said just one picture help you understand what actually is 4D printing... so if you ask me , Bruce can you 4D Print ?

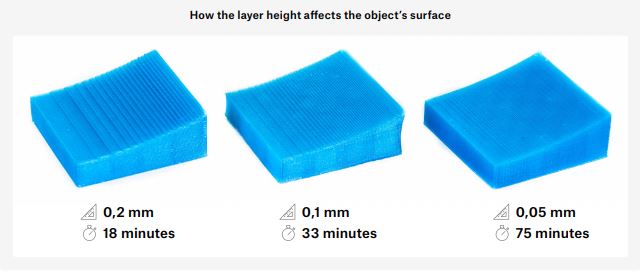

I will ask you check this smart 4D model 3d printable design. https://fab365.net/ Build 3D online(B3D) always help customer select the best setting for their model after check one by one manually. Our client do not need to worry the setting on 3D print. Just in case if you interested to see how is the setup, what quality you could select. These are the commons setting for FDM/FFF 3D print technology. Layer height – sometimes also called the “Z-axis resolution” has a major impact on both print times and overall surface finish of the printed object. Higher values lead to faster prints and more visible layers on the surface of the object. This effect is especially prominent on surfaces that are nearly parallel to the print bed. Most of the time, layer heights of 0.15mm - 0.20 mm are preferred. Lower layer height leads to more detailed prints (less noticeable layers), however, the printing time is extended. We use PrusaSlicer has a function for configuring variable layer height - it means we will help choose which parts of the object will have lower layers (detailed or sloped parts) and which parts can have increased layer height to achieve higher print quality and fastest print time.

What is 3D printing? 3D printing is an automatized process, which enables manufacturing of real physical objects based on digital data (3D model). How much does it cost to run a 3D printer? Highest costs come from the machine (3D printer) & material (filaments). The price for printing a single object depends mainly on its weight. use normal FDM 3D printing for an example: our price is from RM0.75/gram - RM1.5/gram. SLA is start from RM3.5/L. SLS and SLM you could send us the model for quote. Is FFF/FDM 3D printing considered eco-friendly? As with many of manufacturing methods, even in 3D printing part of the processed material ends up as waste (supports, failed prints). However, a large majority of 3D printing materials can be recycled. The most used filament, PLA, is actually biodegradable because it’s made of starch. Also, another thing to consider is the fact that thanks to 3D printing, we are now able to repair things that may have very well ended up in waste, which would be a bigger ecological burden. A handle for a fridge can be one of the examples. Is it possible to print a house? Yes, there’s already a number of successful attempts using concrete or similar materials. It works the same way as 3D printing with plastics. Can 3D printers print human organs? Not yet. However, scientists from all over the world are working hard to make this possible. There are news published about this topic almost every day. The problem (and the challenge) is the fact that human organs are incredibly complex and dependant on other organs. Scientists are focusing on printing tissues for less-complex organs, for now. Can I print objects larger than the print surface? Yes, it’s possible to cut the model into pieces and glue them together after printing. What is the difference between SLA and FFF technologies? FFF (or FDM) 3D printing uses filament as the source material – a strand of plastic. The material is melted and extruded through the nozzle, which is a part of an extruder. SLA, on the other hand, is based on solidifying of liquid resins using UV light. Objects printed on FFF 3D printers have more visible layers compared to SLA. On the other hand, SLA printing has different disadvantages - such as the use of liquid resins, which are potentially harmful chemicals. How long does a print job take? A simple question that is difficult to answer. It depends on many different factors: primarily, it’s the size of the printed object, but also the density of the infill, number of perimeters, lower and upper shells, nozzle diameter, layer height, model complexity, number of supports and other factors. Printing a figure 5 cm tall will take a couple of hours. However, with large and complex objects, you can easily get into dozens of hours of printing. You could send your model to use for check. Can I print a cup or a plate and use it for drinking and eating? Yes, but there’s a couple of things to keep in mind! PETG and PLA are harmless plastics that can get in touch with food. However, it’s not advised to use the printed objects for eating or drinking without post-processing them first. Tiny gaps in layers are perfect for accumulation of bacteria and it’s nearly impossible to clean these parts well. Before you start using a printed cup, use food-safe epoxy to coat Is it possible to 3D print a gun?

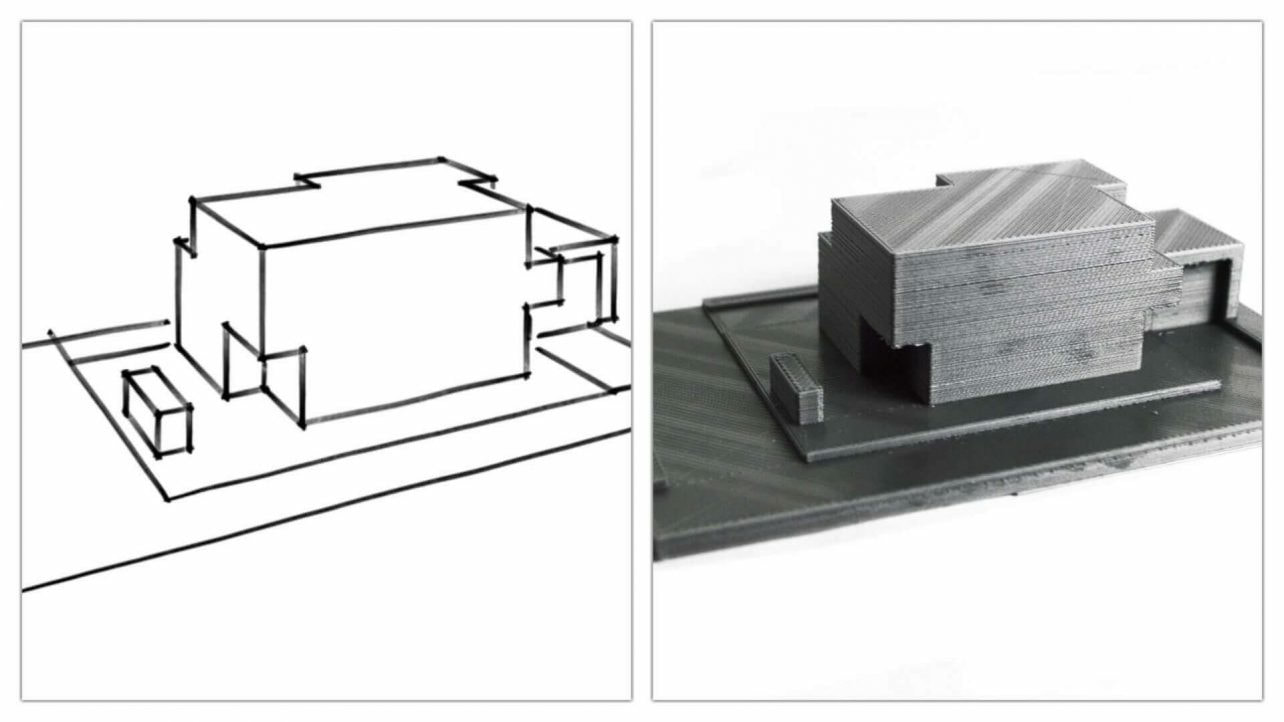

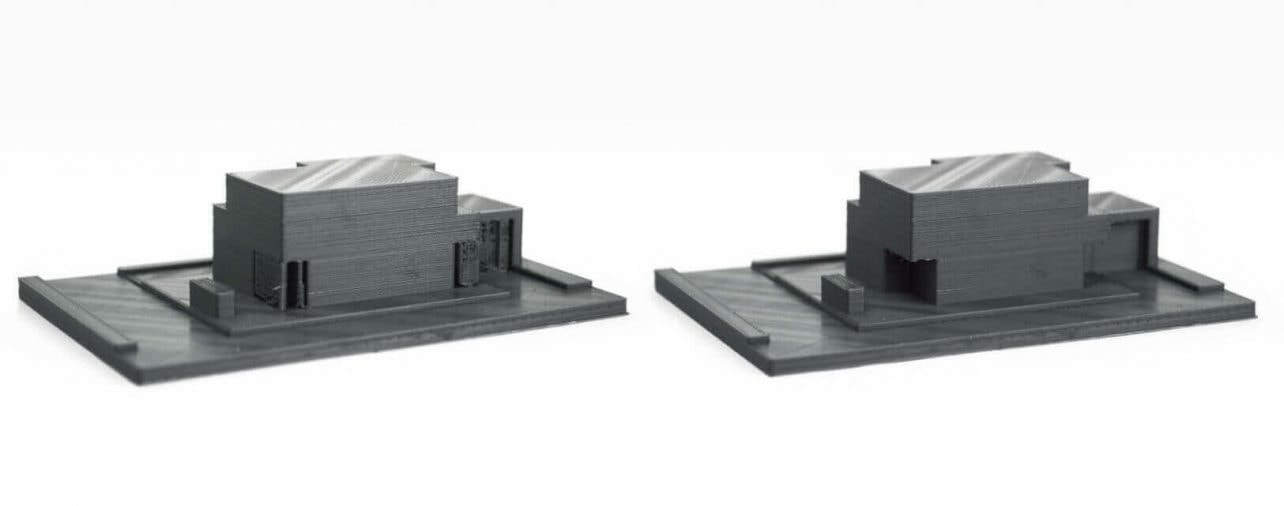

Theoretically, yes. If you take your time with post-processing, it can even look quite real. Would you put a real bullet in a plastic gun and pull the trigger, though? No? Neither would we! The plastic gun would most likely shatter in your hand and hurt you. Also, it would be impossible to take this gun through a metal detector, because the shell casing of the bullet would trip an alarm anyway. So maybe you’re thinking: “How about using metal powder (SLS printing)?” Yes, that would be theoretically possible. However, this scenario is completely pointless due to the high price of manufacturing. If you, for whatever reason, want to produce a gun at home, a simple lathe is more than enough. 3D printing architecture models have become an interesting alternative. Learn how to easily 3D print your architectural models. Model building has helped architects represent their projects for as long as we can think. The initial draft is transferred into a scaled architectural model. Typically, architectural models are made of cardboard, wood or other moldable materials. Architects need models to study the aspects of their design. It is often changed in order to get a perfect concept of their idea. Whether it is just an ad-hoc model or a fully developed project, all this can be displayed with a 3D printer. Due to the stored files, it is possible to change digital structures easily and print the model again. Also, the architect can convince his customer thanks with a faultless and precise model. You can alter your digital model, try out variations on the fly and visualize problems easily. Once you start designing in the digital domain, the benefits of 3D architectural models are pretty clear:

The following tutorial will guide you through the process of 3D printing architectural models. Without getting out your model-building material, you’ll be able to quickly visualize your idea. It will definitely be more laid back than building your model by hand. Please be advised, that 3D printing an architectural model takes on average around 3-9 hours. The most complicated part is to get the architectural models converted for 3D printing – but we got you covered here. The beauty of 3D printing is: You don’t even have to own a 3D printer to get to a great architecture model – you can always resort to 3D printing services (get the best price by email your model here). The most complicated part is to get the architectural models converted for 3D printing – but we got you covered here. by Max Gicklhorn The models printed with MSLA technology with Phozen shuffer XL machine. and post processing by Bruce. if you interested to get one for your collection you can contact us~ Miniature story

Chinese or Imperial guardian lions, also known as lion dogs or foo dogs in English, are a traditional Chinese architectural ornament. Typically made of stone, they are also known as stone lions or shishi. The concept, which originated and became popular in Chinese Buddhism, features a pair of highly stylized lions—often one male with a ball and one female with a cub—which were thought to protect the building from harmful spiritual influences. Used in imperial Chinese palaces and tombs, the lions subsequently spread to other parts of Asia including Japan (see komainu), Korea, Tibet, Thailand, Burma, Vietnam, Sri Lanka, Nepal, Cambodia, Laos, Malaysia, and Singapore. Dear customer,

Please be informed that B3D-Online website will be closing from 31st JAN - 6 Feb and we shall resume operation on 7th Feb. All orders and enquiries received during this period will be processed from 7Feb onwards. Sorry for the inconvenience caused. B3D wish you Happy Chinese New Year and Happy Holiday. Regards by founder, Bruce |

Archives

August 2023

Categories |

B3D-ONLINE (AKA Build 3D online) Presented by B3D Group Sdn Bhd. Founded By Bruce Mui . Click for T&C.

RSS Feed

RSS Feed