|

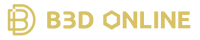

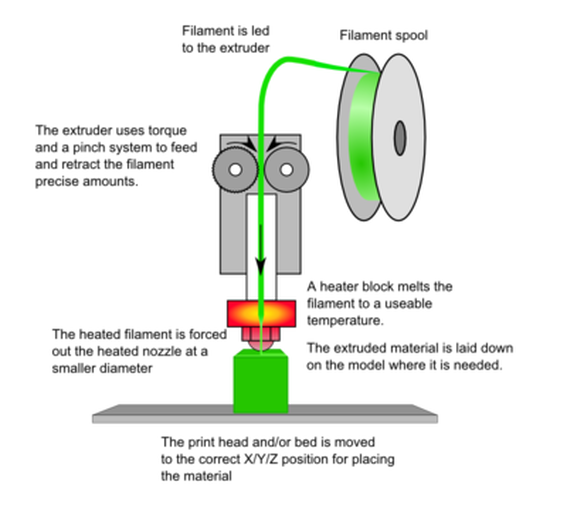

You may already read alot of news or media talk about printing rabbit heart , boat or building. Those media always make 3D printing technology sound like just one push button it done by itself. Well I am Bruce lets back to basic. 3D Printing is a desktop version of Additive manufacuring. Yes, in theory it can build amos everything , But! 3D Printing technology is not one thing. is a category it includes the plenty type of technology. One of the most common desktop 3D Printing is FDM technology. FDM Fused Deposition Modeling/ FFF Fused Filament Fabrication side noted: This two are same thing. If you interested why one technology got two name click here FDM/FFF the additive manufacturing method in which a detail is created layer by layer by melting a plastic wire and applying it through a heated nozzle. check the picture below : FDM Method is very simple. but when you search FDM printing . they are a lot of brands and got the big difference in pricing, from a few hundred Ringgit to a few Hundred Thousand Ringgit. It is confusing if you don't understand. The technology is simple and it exists more than 30 years. but to make it work correctly that is another story. FDM material is mainly with thermal plastic. Most popular are PLA and ABS, PETG but (non-comprehensive) also printable like PP, Nylon, HDPE, ABS HDPE blend, PCL, Polycarbonate,Low melting point metals etc. Ofcause not all Machines can run all materials, it limited by the machine components. You do not expect a thousand Ringgit China machine to print Nylon without modifying replace the machine with an expensive part and casing. If you are willing to spend time into the mod. yeah, you could save little money. Most of the time. PLA PETG are supported for most of the machines.ABS material will require heated bed and case to avoid temperature drop causing warp or crack. And industrial FDM 3D printer can cost alot. it depend on printing size, feature material , machine structual software etc. one important thing is all well calibrated FDM machine no matter cheap/ expensive they can achive exact same result by using normal material like PLA. here is some sample. by default most of the printer come with 0.4mm nozzle and print on 0.2mm Layer height to achinve higher find detail either lower down the layer height setting or replace smaller nozzle and it will causing the 3d printing time longer. To achive high quality 3D printing service , in FDM catogory , We ( B3D-online.com ) mainly use The BEST OVERALL 3D Printer Original Prusa i3 MK3S (Best 3D Printer Feature all3DP 2019 Winter) FDM is the basic it support by major hobbies/Engineer/inventor market/home use Market. We help most of the customer design and build part with this technology. With our reliable and affordable service you can forcus on your Idea. To know more about FDM limitation you can click the link below

https://www.b3d-online.com/blog-news/ffffdm-3d-print-101-layer-height-infill-support Next story we will share about Next level of detail: What is Resin/MSLA/SLA/DLP 3D printing

1 Comment

|

Archives

August 2023

Categories |

B3D-ONLINE (AKA Build 3D online) Presented by B3D Group Sdn Bhd. Founded By Bruce Mui . Click for T&C.

RSS Feed

RSS Feed